Our Products

Our team consists of highly qualified and motivated professionals, who are all experts in their field. With many years of experience in the industry, they have the expertise to provide comprehensive, first-rate services to our clients.

With a vast selection of materials available, we find the right pipes for any enviroment.

The selection of material for oil pipelines is a critical decision that affects the pipeline's strength, durability, corrosion resistance, and cost. Here are five materials that are commonly used in oil pipeline construction:

Finding the perfect solutions for your project needs.

The diameter of the pipeline is a crucial parameter that determines the volume of oil that can be transported, the pressure required to pump the oil, and the overall cost of the pipeline. For long-distance oil transportation, larger diameters are generally preferred to allow greater volumes of oil to be moved.

Cutting edge technology goes into the latest pipeline coatings to preserve and protect you investment

When selecting a coating, factors such as local soil chemistry, salinity, temperature range, UV exposure, and mechanical stresses (like ground movement) must be taken into consideration. The coating should also adhere to any relevant international and local standards, like those from the American Petroleum Institute (API) or the National Association of Corrosion Engineers (NACE). Consulting with coating manufacturers or specialists can be beneficial in making an informed decision.

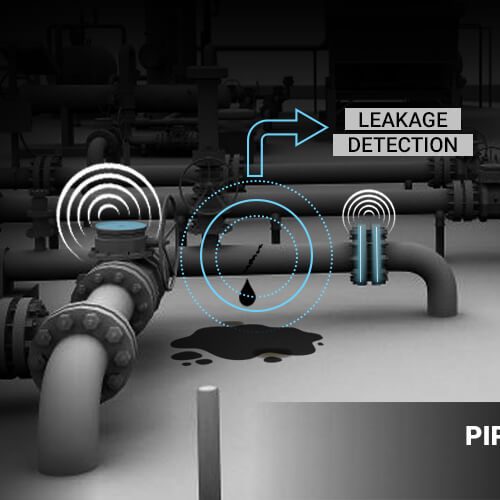

We aim to provide fully formed solutions to make sure you minimise any loss of product.

Oil pipeline leak detection systems are crucial for maintaining the integrity and safety of a pipeline. They can detect leaks in their early stages, mitigating potential environmental damage and financial loss. Here are five top-rated systems based on technology, effectiveness, and reliability

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.